SMELTER & REFINERY SHUTDOWN MANAGEMENT

CLIENT

Major Smelter and Refinery Operation

OBJECTIVE

Xenco was engaged to support the largest shutdown ever executed at a major smelter and refinery operation. Initially tasked with providing expert guidance on what a successful shutdown would entail, Xenco’s role quickly expanded to managing the entire project, including overseeing both maintenance and project activities and the client’s contractors.

THE CHALLENGES

The large scale of the refinery required extensive coordination and planning, with the following key challenges.

- Plant shutdown total labour hours were greater than 2.5millon.

- Daily contract numbers peaked at 2,700, creating large-scale interactions and management.

- High-risk operations demanded strict safety measures across all activities.

- Ancillary equipment across the plant had to be included in the shutdown.

- Large cranage (1200t) requiring complex site establishment to lift and shift large equipment which required precise planning.

- Existing plant condition was poor, adding complexity when removing large, corroded equipment.

APPROACH

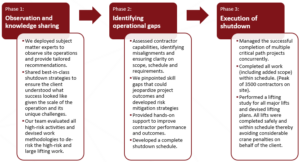

Our team successfully delivered the shutdown project through a structured, three-phase approach, with a strong emphasis on safety.

OUR RESULT

Despite a challenging environment with significant risk and safety concerns, our team successfully delivered the largest shutdown in the site’s history.

Key outcomes included:

Reduced overrun by 30 days compared to the previous total plant shutdown.

Achieved startup two days ahead of plan, resulting in $2M savings.

Maintained budget control within +/- 5%.

Over 70 contract companies engaged.

Zero injuries throughout the project.

Completed on schedule.