ASSET RELIABILITY TRANSFORMATION

CLIENT

Leading Australian Industrial Producer

OBJECTIVE

Xenco was engaged to support an asset reliability transformation aimed at minimising fixed equipment downtime, increasing production volumes, and improving profitability. The goal was to deliver a short-term uplift in performance, embed sustainable improvement processes, and implement Asset Strategy software to enable data-driven asset management across the operation.

THE CHALLENGES

The engagement was delivered under several significant constraints, requiring a focused and adaptive approach:

-

Resourcing Limitations – Only one full-time Xenco consultant supported by part-time site resources.

-

Urgent Production Pressures – The site required immediate reliability improvements to meet demand.

-

Outdated and Inconsistent Systems – Significant gaps in asset standards and processes created a fragmented starting point.

-

Changing Priorities – Frequent scope and schedule shifts driven by emerging site needs and high turnover within the client team.

APPROACH

Xenco applied a structured, data-driven, and collaborative approach, combining asset management expertise, change leadership, and project discipline to guide the transformation. The consultant also leveraged Xenco’s broader specialist network, including reliability engineers and master data analysts, to address emerging technical challenges and maintain momentum.

Key focus areas included:

-

Maintenance Strategy Optimisation

-

Reviewed and refined over 8,000 equipment strategies.

-

Transitioned optimised strategies into the client’s enterprise asset management system.

-

Developed a suite of documentation covering continuous improvement cycles, bad actor analysis, master data quality, and governance workflows.

-

-

Standards & Process Development

-

Established new asset management standards, processes, and governance structures to embed sustainable practices.

-

-

Asset Strategy Software Implementation

-

Configured and integrated Asset Strategy software with SAP, creating a centralised, data-driven approach to asset performance management.

-

-

Workforce Capability Building

-

Trained more than 50 site-based engineering and maintenance personnel in reliability optimisation and system tools.

-

Built ownership and capability to ensure improvements were sustained post-project.

-

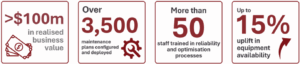

OUR RESULT

The transformation delivered immediate impact and long-term value for the client.

Key outcomes included:

-

Business Value Realised – Over $100 million delivered through reduced downtime and increased production.

-

Maintenance Plans Deployed – More than 3,500 plans configured and embedded into SAP.

-

Workforce Capability Uplift – 50+ personnel trained in reliability processes and tools.

-

Reliability Improvements – Up to 15% increase in equipment availability across targeted plants.

-

Sustainable Foundations – Full suite of standards, tools, and processes implemented to support ongoing safety, reliability, and cost performance.